ABOUT US

WORLD CLASS FACILITIES

‘Excellence and Quality’ is our mantra and reflected in the technology, processes and certifications of the manufacturing units.

The Cigarette manufacturing units located in Rabale and Guldhar have top brass technology partners like Philip Morris, G.D., Comas, SMC, Luwa, Forbes Marshall, Honeywell, Miebach, Nefab, Kaesar, and the Haulotte Group. Our units also have top certifications of ISO 9001, 5001, 14000 and OHSAS. The Guldhar factory is the first one in the tobacco industry to have a Social Accountability 8000 certification and best processes including Six Sigma, TQM, Haichi Ban, 5 S and Kaizen.

.jpg)

ABOUT US

RESEARCH AND DEVELOPMENT

Godfrey Phillips India boasts state- of- art research and development facility that employs some of India’s best scientists, cigarette designers, blenders and flavourists.

The Insight Tobaccocraft Institute is the first laboratory in the Indian tobacco industry to be accredited with an ISO 17025 certification, as well as recognition from the government’s Department of Science and Technology.

Our qualified blenders here, hailing from specialised fields of agricultural sciences, have mastered the art of tobacco selection and blending. Combining the traditional art of tobacco selection with advanced filtration technology and modern methods, we craft deeply flavorsome and satisfying smoking experiences. We are equipped to develop various cigarette blends matching the palette of customers across the globe, besides meeting the regulatory requirements of different parts of world. By being located alongside our production facilities, our R&D team can also combine synergies and create the best blends for domestic and international markets, based on customer needs.

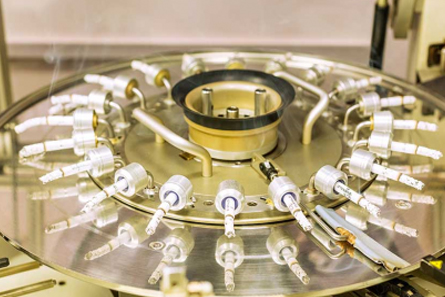

In order to bring greater reliability to our analytical results, we also take part in initiatives such as the Asia Collaborative Study (ACS). Our participation each year, along with 58 other prominent cigarette companies of the world, such as PMI, BAT and JTI, helps cross calibrate our results with the best in the business. Our Z- scores, which determine the quality of analytical data, vis-à-vis the best in the world, have proven to be excellent year on year. The Insight Tobaccocraft Institute also makes blending and product development easy with its state-of-the-art, automated pilot plant, which is capable of processing and making sample cigarettes at a faster pace in relatively smaller quantities. Continuous improvement, reverse engineering, creating product differentiation, and innovation are the core strengths of the Insight Tobaccocraft Institute.